Window Technologies: Frame Types - Metal Frames

Metal Frames

The biggest disadvantage of aluminum as a window frame material is its high thermal conductance. It readily conducts heat, greatly raising the overall U-factor of a window unit. In cold climates, a simple aluminum frame can easily become cold enough to condense moisture or frost on the inside surfaces of window frames. Even more than the problem of heat loss, the condensation problem spurred has development of better insulating aluminum frames (see Metal with Thermal Break). In hot climates, where solar gain is often more important than conductive heat transfer, improving the insulating value of the frame can be much less important than using a higher-performance glazing system.

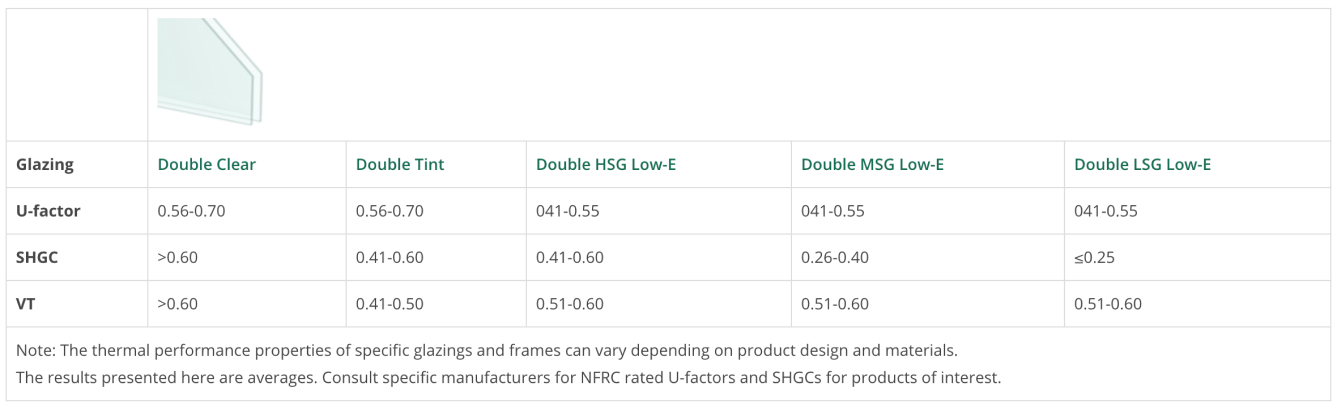

Whole Window Properties – Metal Frames

Metal Frames with Thermal Break

Aluminum window frames are light, strong, durable, and easily extruded into the complex shapes required for window parts. Aluminum frames are available in anodized and factory-baked enamel finishes that are extremely durable and low-maintenance.

Aluminum window frames are light, strong, durable, and easily extruded into the complex shapes required for window parts. Aluminum frames are available in anodized and factory-baked enamel finishes that are extremely durable and low-maintenance.

The biggest disadvantage of aluminum as a window frame material is its high thermal conductance. It readily conducts heat, greatly raising the overall U-factor of a window unit. In cold climates, a simple aluminum frame can easily become cold enough to condense moisture or frost on the inside surfaces of window frames. Even more than the problem of heat loss, the condensation problem has spurred development of better insulating aluminum frames.

The most common solution to the heat conduction problem of aluminum frames is to provide a “thermal break” by splitting the frame components into interior and exterior pieces and use a less conductive material to join them. Current technology with standard thermal breaks has decreased aluminum frame U-factors (heat loss rate) from roughly 2.0 to about 1.0 Btu/hr-sq. ft-°F. In hot climates, where solar gain is often more important than conductive heat transfer, improving the insulating value of the frame can be much less important than using a higher-performance glazing system.

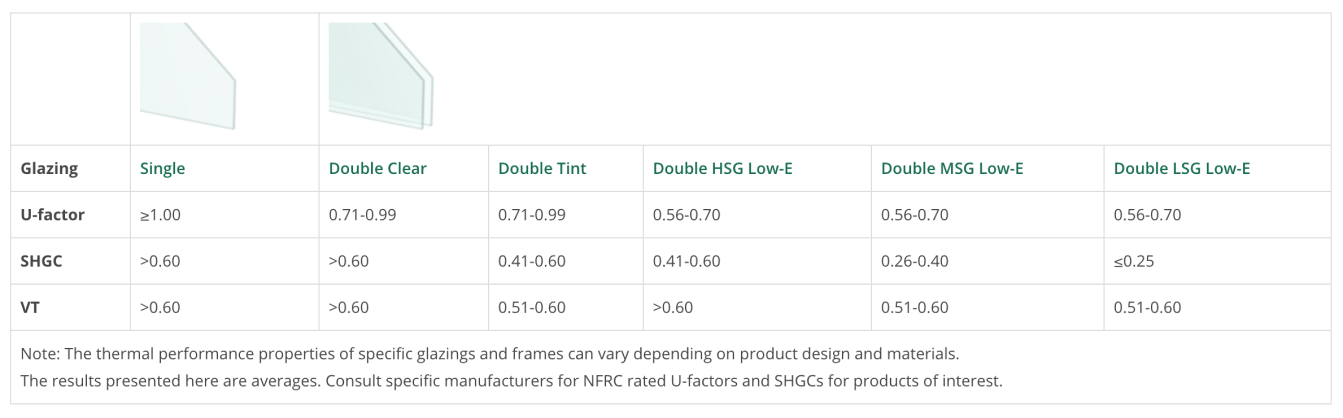

Whole Window Properties – Metal Frames with Thermal Break