Types and Parts

The technologies that make windows efficient go beyond just the glass panes – they are found in the frames and inside them as well, including the internal spacers that hold the glass in place. NFRC’s ratings system evaluates all these parts of a window to establish its energy-efficiency ratings:

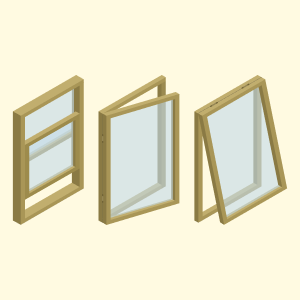

Window Types

Traditional operable window types include the projected or hinged types such as casement, awning, and hopper, and the sliding types such as double- and single-hung and horizontal sliding. This section on Window Types describes how these typical windows work.

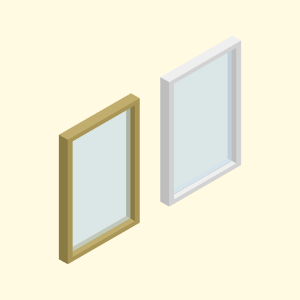

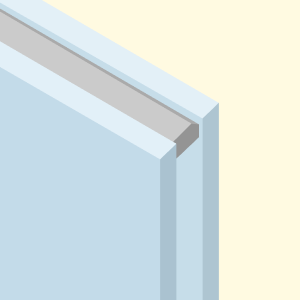

Window Frames

The material used to manufacture the frame governs the physical characteristics of the window, such as frame thickness, weight, and durability. It also has a major impact on the thermal characteristics of the window. This section on Frame Types describes the performance impact of different frame materials and how they influence the total window performance.

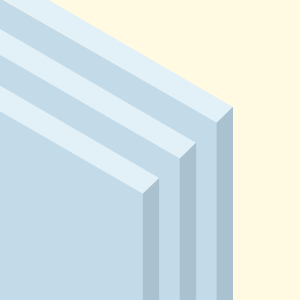

Window Glazing

Single-glazed windows have one pane of glass and typically cost less. Double-glazed windows have two panes and balance cost and efficiency. Triple-glazed windows use three panes and are the most efficient.

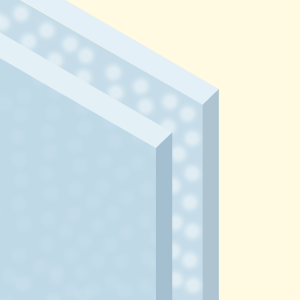

Low-e Coatings

Low-emissivity (Low-E) coatings are transparent metallic layers, thinner than human hair, applied to the surfaces of glass. This coating prevents heat from entering buildings during the summer months and escaping from them during the winter.

Gas Fills

Windows with more than one pane have a fixed gap between them, and filling that space with a safe, odorless, and colorless gas boosts efficiency. In cold climates, the gas reduces heat loss through the glass. In hot climates, it reduces unwanted heat gain.

Spacers

These small parts fit between multiple panes of glass and hold them in place. Using specific materials and shapes can boost efficiency.

Check out Energy Saver for additional information about window types and technologies.

Windows 101 for Scientists and Inventors – Windows Basics

In this video, the Lawrence Berkeley National Laboratory‘s experts explain the basic nomenclature and terminology for windows and window components.